RELIABILITY

Unmatched reliability.

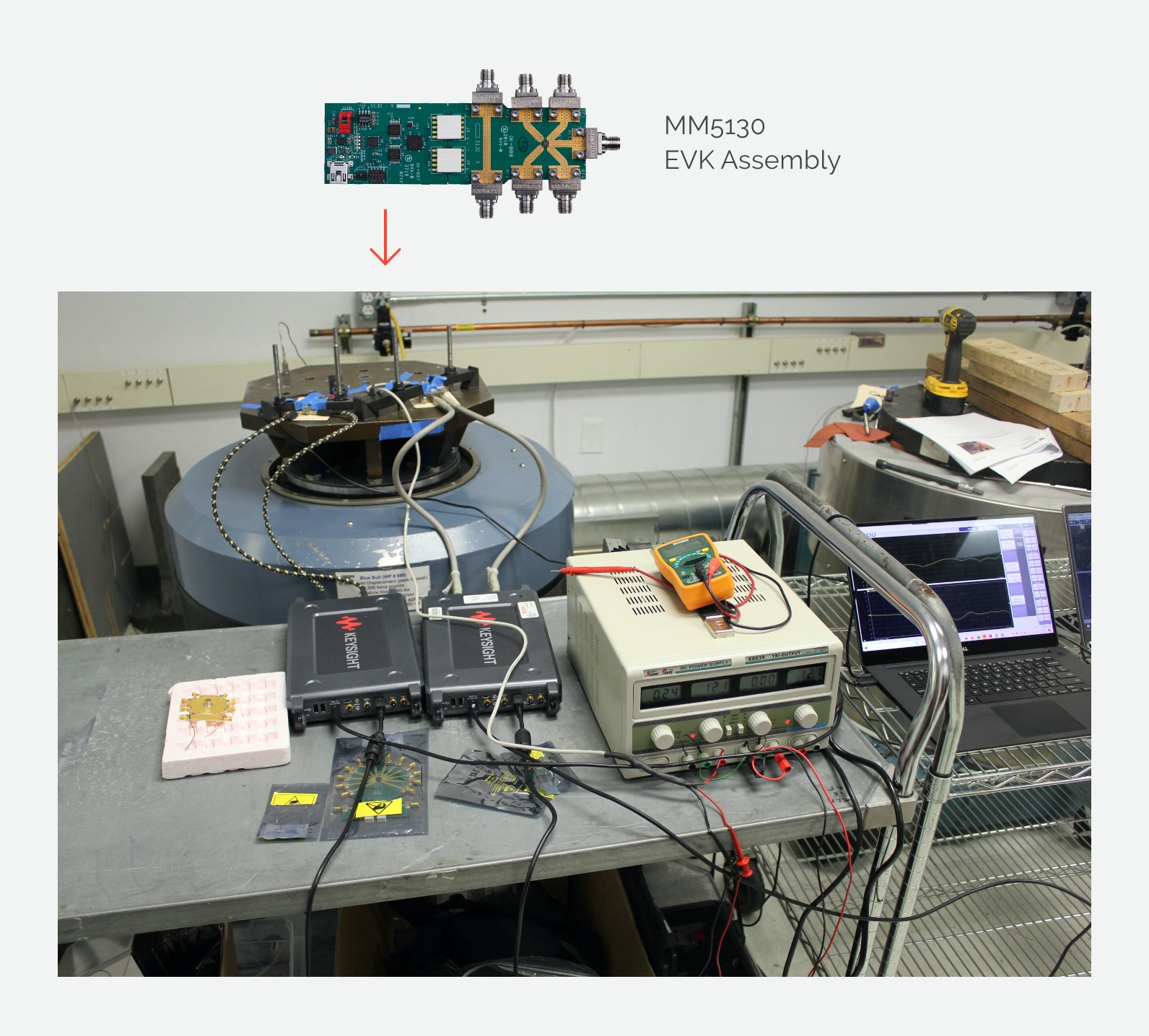

While our GE heritage offered us a number of development advantages, the support of industry leaders helped drive reliability at scale.

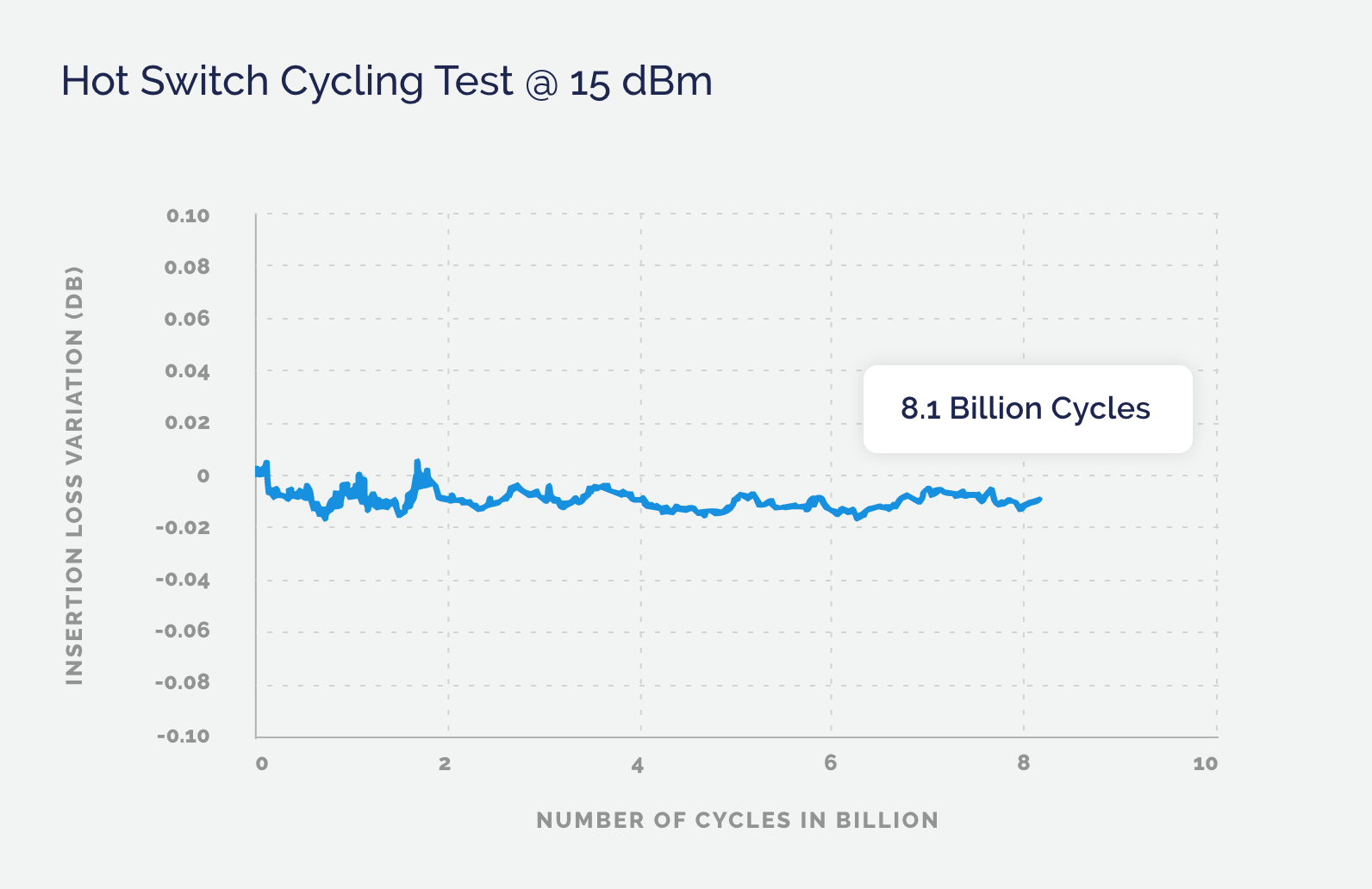

The Ideal Switch benefits from a metal conductor and a physical air gap. We have developed metal alloys for the Beam and Contact to ensure an absence of metal fatigue. As a result, we have a moving part that can operate at a stable performance across decades. Today we guarantee >3 billion actuations, with a roadmap to >20 billion actuations. As a comparison, electromechanical relays need to be replaced after <10 million actuations.

Key takeaways

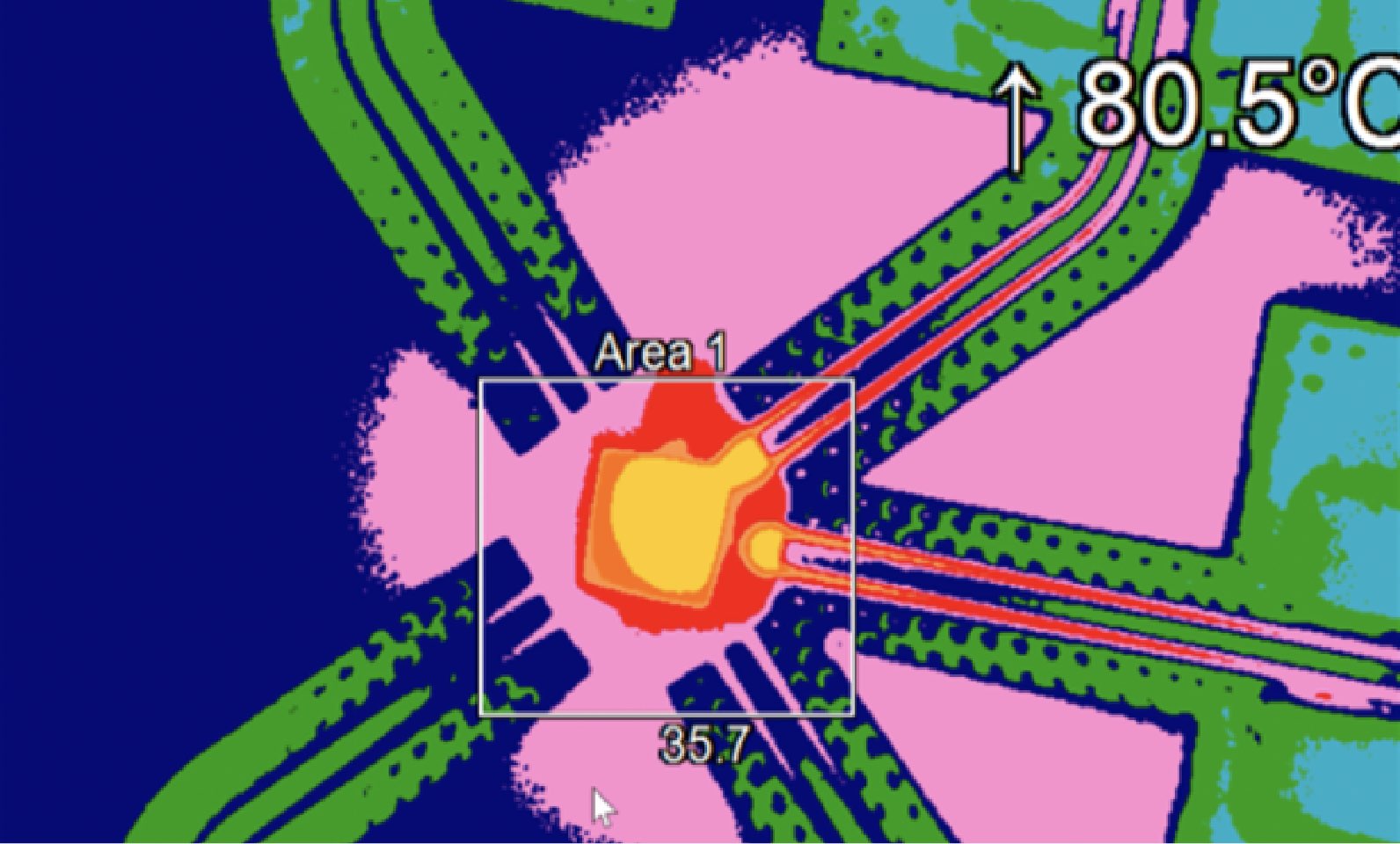

Solid-state switches are also called “semiconductors,” because they are not great conductors. Their relatively high resistance means they can heat up considerably, at times requiring heat-sinks and even fans. The Ideal Switch uses an extremely low-loss metal conductor and, as a result, does not generate much heat.

This is a single MM5130 Ideal Switch heat profile operating at room temperature. A comparable semiconductor switch would require a bulky heat-sink and even higher power inputs to deliver the same signal strength and stability.

MM5130, 25 W 2.4 GHz CW load, no heat sink

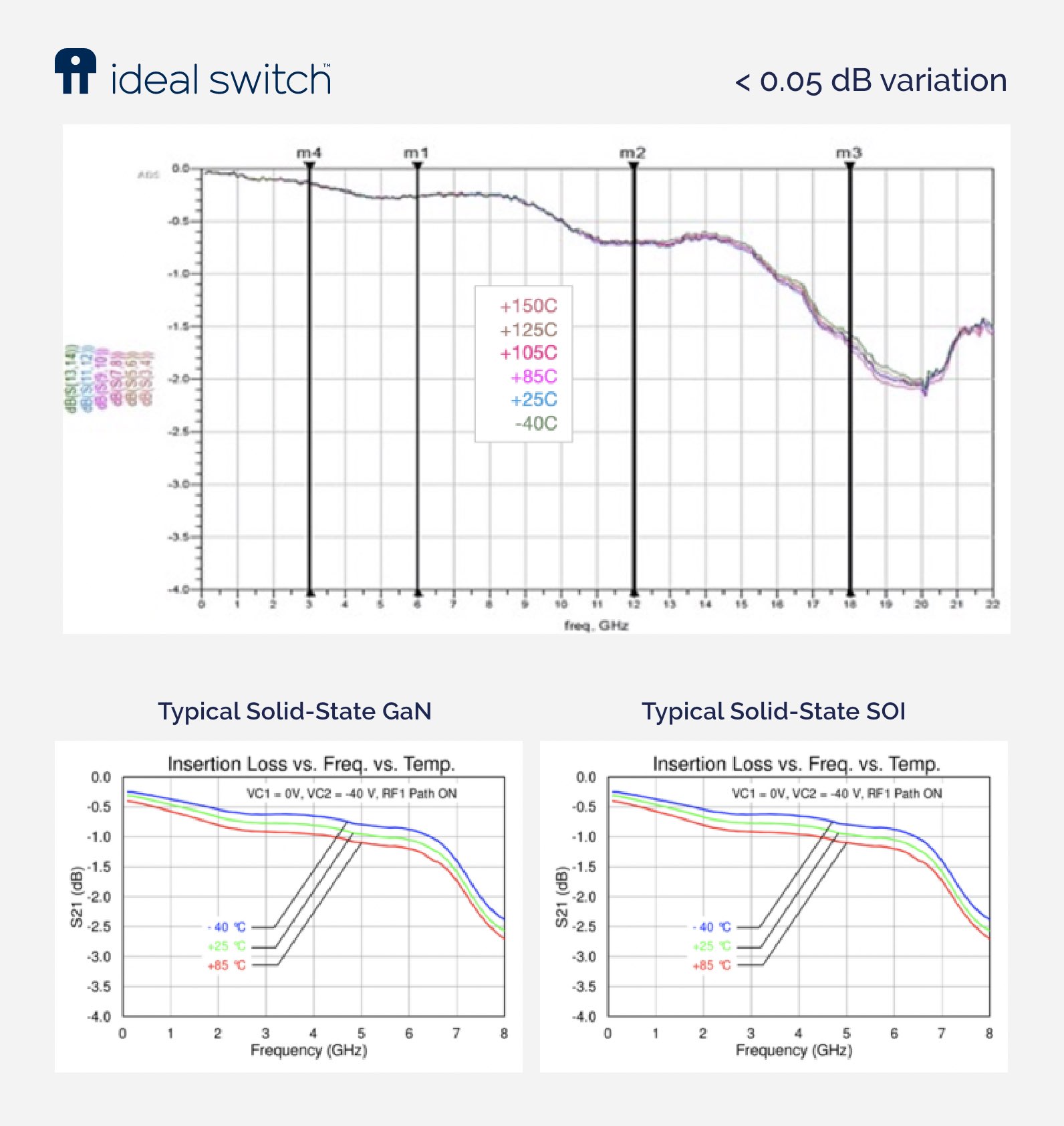

In addition, the Ideal Switch performs well in extremely hot environments. Or cold ones, for that matter. The materials we’ve developed have proven to maintain their performance over broad temperature ranges.

The Ideal Switch has superior temperature performance from -40C to +85C with much lower operational variation compared to solid-state technologies.

Environmental Performance: -40C to +150C

Environmental Performance: Cold

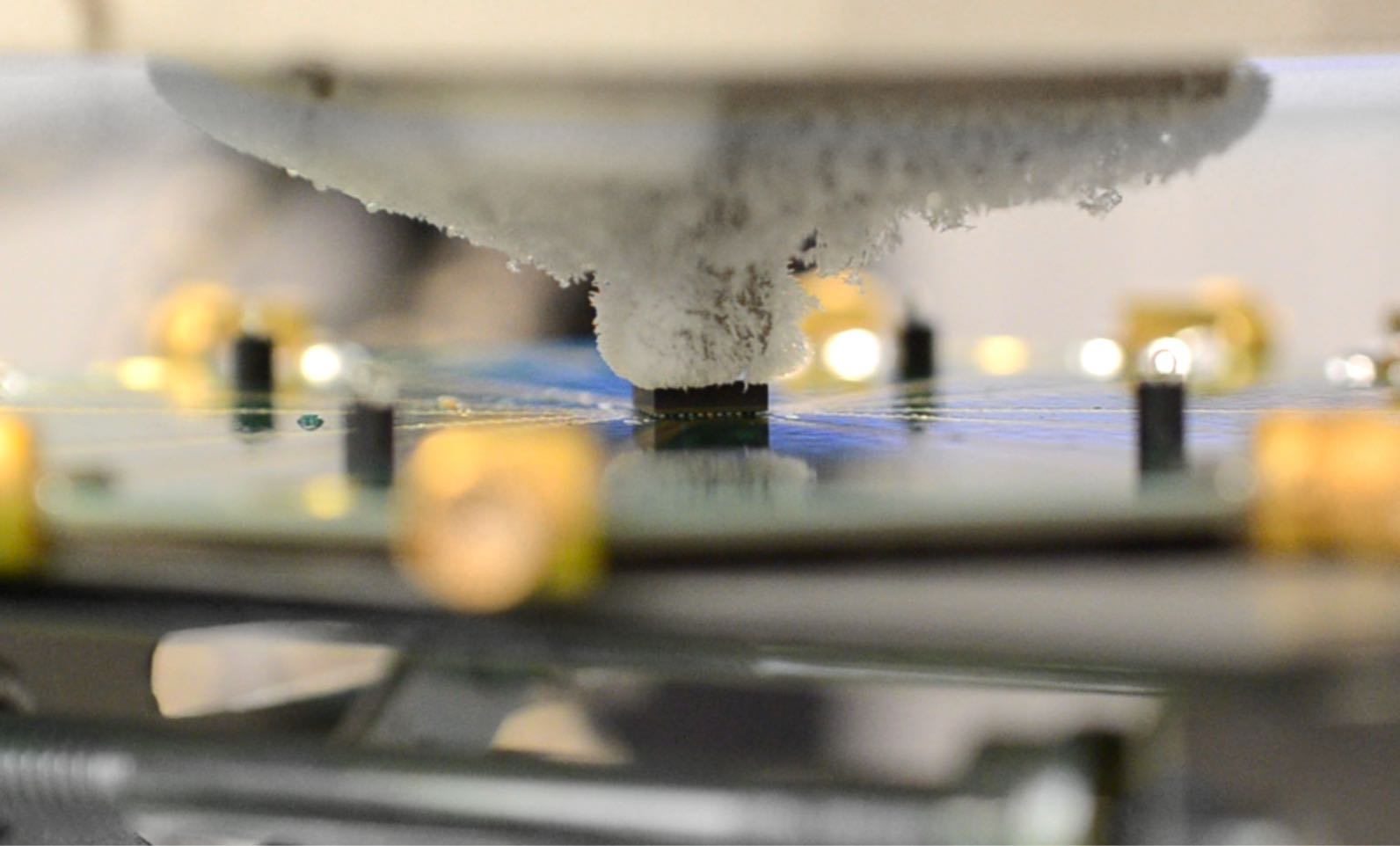

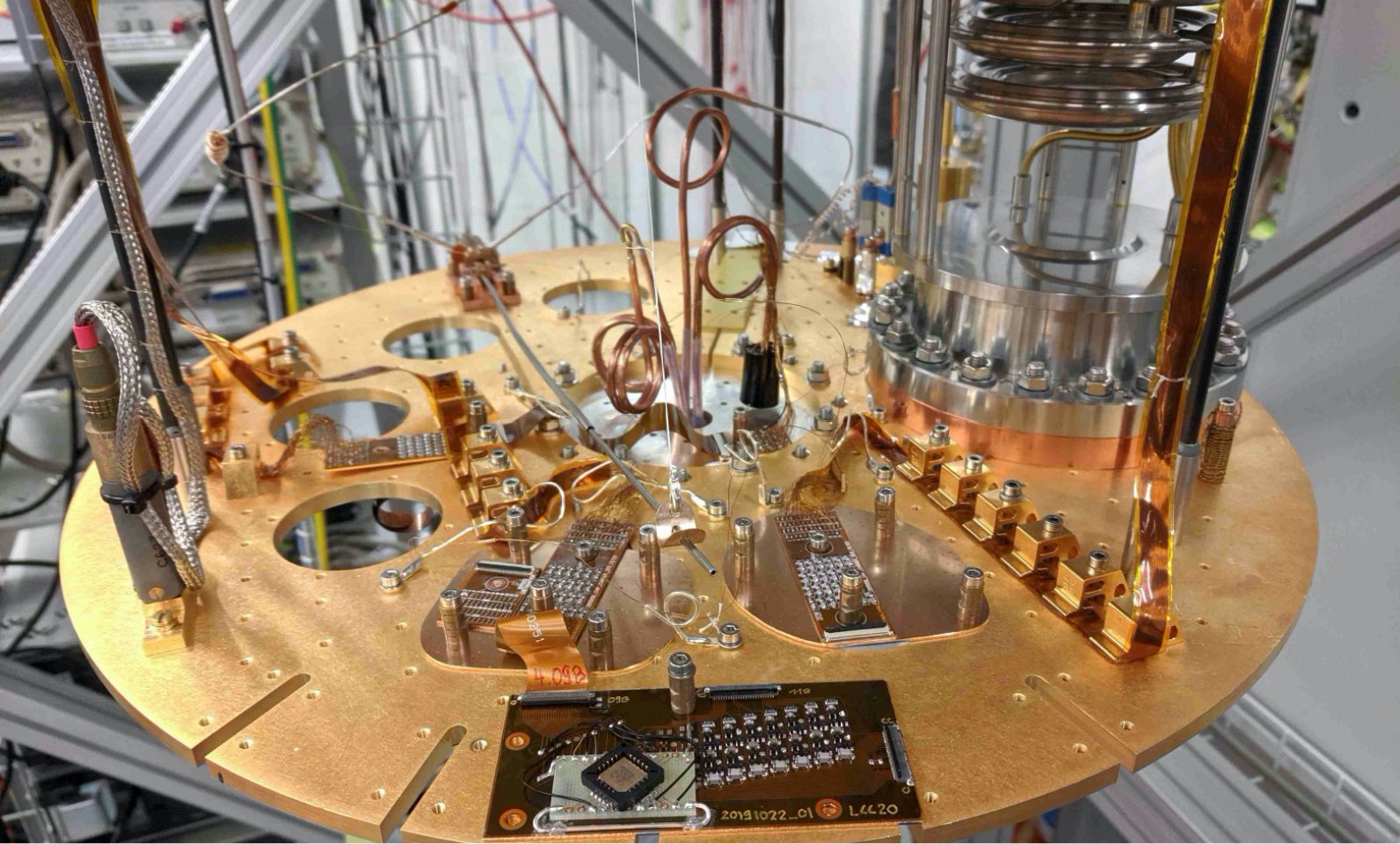

We have even placed our Ideal Switch in a liquid nitrogen bath and a dilution refrigerator. In both cases the Ideal Switch maintained full functionality.

Ideal Switch turned OFF in bath of liquid nitrogen: -196C (77 K)

Ideal Switch turned ON in bath of liquid nitrogen: -196C (77 K)

Ideal Switch setup in dilution fridge: <10 mK

We are taking advantage of these temperature performance characteristics and will apply our Ideal Switch technology to high-power applications. We will be introducing Ideal Switch solutions capable of handling kW of power in the near future.

Electromechanical relays have a number of moving parts, each of which have considerable mass. When exposed to intense shock or vibration, the adverse movement of those parts can compromise the relay’s performance. Or they can break altogether and render the relay inoperable.

While the Ideal Switch also features a beam that actuates, it is so small that its mass is negligible. As a result, any Ideal Switch delivers constant performance even during extreme shock and vibration exposure.

The Ideal Switch exceeds IEC 60601/60068 and MIL-STD 810G standards. Electromechanical relays subjected to the same test fail. We are currently conducting tests exposing the Ideal Switch to even greater physical stressors to understand its outer bounds.

Environmental Performance: Shock & Vibration